Elevate Orthopedic Care and unleash the power of Mobile X-ray Technology!

Discover the possibilities for optimizing patient care and treatment outcomes, from enhanced mobility to unparalleled precision. Uncover how our portable units empower orthopedic practitioners with accurate diagnoses and tailored treatment plans, from fractures and dislocations to joint degeneration.

Application

Experience the convenience and efficiency of the JuvaRay Handheld X-ray Imaging System, designed with fixed exposure parameters for effortless operation. Ideal for examining limbs and chest areas*, it offers precise imaging without the need for mammography.

Ease of Use

Designed for mobility and ease of use, our units enable orthopedic care to be delivered anytime, anywhere, with minimal disruption to workflow.

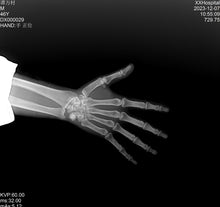

Image Quality

Precision Imaging, Enhanced Outcomes: Mobile X-ray Excellence. Witness the clarity and precision of mobile X-ray images. With advanced technology and superior image quality, our units provide orthopedic surgeons with the insights they need for confident decision-making and successful outcomes.

Safety and Compliance

Prioritizing Safety: Mobile X-ray Assurance in Orthopedics. At Juvawave, safety comes first. Our mobile X-ray units adhere to the highest safety standards and regulatory compliance, ensuring the well-being of patients and practitioners during orthopedic imaging procedures.

Cost-Effectiveness

Invest Wisely: The Economic Advantages of Mobile X-ray for Orthopedics. Discover the financial benefits of integrating mobile X-ray technology into orthopedic practices. From reduced operational costs to enhanced patient outcomes, our units offer a compelling return on investment for orthopedic surgeons and healthcare facilities.

Training and Support

Empowering Orthopedic Practices: Mobile X-ray Education and Support. Seamless integration starts with comprehensive training and ongoing support. At Juvawave, we’re committed to equipping orthopedic practices with the knowledge and resources they need to maximize the potential of our mobile X-ray technology.

Advantages of Mobile X-ray vs Stationary X-ray:

Normal stationary X-rays are cumbersome to use and maintain. They require a large space to operate, usually a room, and their user interface is often a lacking component. A mobile X-ray can help to solve these problems and bring about new benefits:

1. Space Efficiency:

Stationary X-rays are large and fixed machines, meaning they usually require a whole room to operate them. Clinics that want to utilize their space in the most effective way can benefit from mobile X-rays, as they can be stored anywhere where a carry-on sized bag could fit.

2. More Imaging Angles:

Mobile X-rays are dynamic compared against their counterpart, the stationary X-ray. Stationary X-rays have a limited amount of X-ray positions and have to stay in a fixed position. Since the mobile X-ray can move around and is not attached to a wall or ceiling mount, it can take a X-ray from almost any angle, helping the health care professional give the best care to their patients.

3. Simpler Interface and Use:

Stationary X-ray systems usually require an X-ray tech, a room for the equipment, and many steps just to get it working. A mobile X-ray gets rid of these requirements. It is easy to get trained to use the JuvaRay handheld X-Ray generator thanks to its icon based software, and it only requires three main pieces of equipment: handheld X-ray generator, receiver panel, and laptop. On top of this, its setup only takes a couple minutes. All these things demonstrate the simplicity and ease of use a mobile X-ray can offer.

4. Immediate Imaging:

Stationary X-rays can require people travel to an imaging facility, but a mobile X-ray prevents this need. A mobile X-ray can be stored in the office easily inside of a pelican case. With compact X-ray on the clinic site, a person can take an X-ray on-site and look at the image a few minutes later.

5. Workflow Improvements:

With a mobile X-ray, there is no need to take a patient from room to room; the X-ray can simply be taken to them. If the patient has difficulty moving, this can help prevent their discomfort and speed up the time it takes for taking X-rays in the clinic. A study conducted in a clinic found that having a mobile X-ray saved them 90 minutes a day. It is plausible to think other clinics could have similar results as well

X-Ray Generator Features:

Operating seamlessly on a Win system computer, this compact device weighs just 2.6kg, ensuring portability without compromising performance.

With dimensions of 265.9x103.6x168.1mm, it fits effortlessly into any medical setting. Crafted from durable metal and steel materials, it guarantees reliability and longevity.

Backed by a comprehensive 2-year warranty and online technical support, our Handheld X-ray Imaging System assures peace of mind and dependable service whenever you need it.

*Note: Not suitable for mammography applications

- Power Source : Electricity

- Warranty : 2 years

- Material : Metal, Steel

- Shelf Life : 2 years

- Parameters : Fixed exposure parameters,easy to operate

- Application scope : limbs and chest,not suitable for mammography.

- Optional : BW-1717X (100um),BW-1012W(120um),bracket

- Operating system : Win system computer

- Weight : 7LBS

- Dimension : 265.9*103.61*68.1mm

How a Flat Panel Detector Works

Flat panel detectors operate through a series of systematic steps:

- X-Ray Exposure: X-rays penetrate the patient's body, with different tissues absorbing varying amounts. This leaves an X-ray "shadow" as the image contrasts which continues on to the detector.

- Conversion to Light or Charge: If the FPD is indirect, the remaining X-rays strike a scintillator material in the detector, converting them into visible light. In a direct conversion FPD, the X-rays are directly converted into an electrical charge.

- Transformation of Light to Charge: If the detector is an indirect type, the light generated in the previous step hits a layer of photodiodes, converting the light into an electrical charge.

- Generation of Image: The electric charges are then captured by a thin-film transistor (TFT) array. This array reads and amplifies the charges, translating them into a digital signal.

- Image Processing: This digital signal is sent to a computer, where it's processed into a digital image. This image is then available for viewing and diagnosis.

- Image Optimization: Finally, the image undergoes post-processing operations such as contrast adjustment, filtering, and other corrections for optimal viewing.

- Through these steps, flat panel detectors facilitate the creation of high-resolution digital images necessary for accurate medical diagnosis and patient care.

How Much Better Are Flat Panel Detectors Than Image Intensifiers?

Some significant differences between newer FPDs and older image intensifier technology make this newer equipment better and safer to use. As a result, most manufacturers are switching to FPD technology. However, which one you choose will depend on your unique radiography needs now and in the future.

One major difference is that the quality of radiographs an image intensifier produces always degrades over time. Also, its technology can create distortions in the peripheral field of view even when it’s still brand new. FPDs, on the other hand, show minimal degradation over time, and the technology behind them is not subject to peripheral distortion. This means they’ll produce higher-quality radiographic images now and in the future.

FPDs and image intensifiers also vary significantly in their radiation dose. It concerns their use while in magnification mode since an image intensifier requires larger radiation doses to magnify the view. On the other hand, an FPD can magnify that same view without increasing the dose, so it generally uses less radiation to produce the same or better-quality images. This makes flat panel detectors safer in the long term for both patients and the technicians or doctors working with them.

Another difference is in size. FPDs are newer technology, so it's no surprise they’re more compact than the older technology. This allows for more working space for the doctors and technicians, allowing for more precise control, especially when working with larger patients. They also have ergonomic benefits because they are easier to move around, improving functionality while relieving long-term stress on the technicians using them daily.

Cost is often an important consideration. Since flat panel detectors are new technology, they generally cost more than older technology that has been around for decades. While the initial cost savings may seem appealing if you are on an especially tight budget, it’s critical to consider the long-term costs.

Remember that image intensifiers are much more prone to degradation over time and have a much shorter lifespan. They also generally cost more to repair. This means that you may have to repair and replace your image intensifier several times before replacing your FPD just once.

It would eliminate all those upfront savings and could make image intensifiers more expensive in the long run.

Advantages of the Flat Panel Wireless Detector:

- reliability

- wireless

- efficiency

- accuracy and informativeness

- easiness in operation

- trust and recognition from doctors around the world.

Frequently Asked Questions

What Is a Flat-Panel Detector in Radiology?

A flat-panel detector (FPD) in radiology is a device that converts X-rays into digital images. Used in various medical imaging techniques, FPDs deliver superior image quality, lower radiation doses, and faster image processing times compared to traditional film-based systems.

What Are the 2 Types of Flat Panel Detectors?

The two main types of flat panel detectors are direct and indirect conversion detectors. Direct conversion FPDs transform X-rays directly into an electric charge, while indirect conversion FPDs first convert X-rays into light and then into an electric charge. Each type has specific strengths, dictating their use in different radiography applications.

What Are Flat Panel Detectors Made Of?

Flat panel detectors are made up of several essential components:

- Scintillator Layer: Typically made of cesium iodide (CsI) or gadolinium oxysulfide (GOS), and functions to convert X-rays into other wavelengths of light.

- Photodiode Layer: Transforms the light into electric charge, often constructed from amorphous silicon.

- TFT Array: A thin-film transistor (TFT) array reads and amplifies the electric charges, and is made from materials like hydrogenated amorphous silicon.

- Glass Substrate: Provides structural integrity to the FPD.

- Electronics: Includes analog-to-digital converters, multiplexers, and other components for image processing.

- Housing: Protects the components and ensures durability, typically crafted from aluminum or plastic.

Panel Specs:

Detector technology: Amorphous silicon Scintillator: CSI

Active area: 17x17 inch

Pixel matrix :3072 x 3072

Pixel pitch: 140μm

Gary scale :16bit

Ghost No ghost

Artifact No artifact

Spatial resolution :3.6LP/mm

Preview image time<3s

Imaging time<5s

KV range: 40KV~ 150 KV